HOW WE WORK

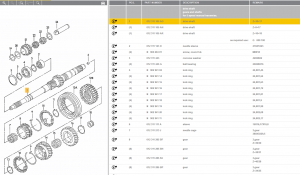

All gearboxes are bench stripped and visually inspected for wear and damage.The units are then cleaned and inspected again. It’s standard to change all bearings & seals in recon & remanufactured gearboxes. With replacement of hard parts as required, such as gears, forks or synchro’s.

It’s at this point we will give you call to confirm work & pricing on gearbox repairs

Gearbox Repairs – Simple Diagnosis

Some simple problems on gearboxes can fixed as a Gearbox Repair which is cheaper when compared to a full Reconditioned Gearbox.

National Gearboxes normally carry repairs out for the motor trade.

When a fault is found during clutch replacement, I.E oil leaking from the input shaft or the gearbox is noisy on idle, you may even notice the oil is contaminated with silvery swarf. The input shaft may also have excessive play. It’s worth noting that when the input shaft bearings have worn,the gearbox will feel a little rough when you turn the input shaft by hand. Any input shaft noise will disappear when you depress the clutch, Crunching 1st & Reverse normally indicates the clutch needs replacement. In cold weather difficult selection of gears [until the car has warmed up] can be an indicator of incorrect [grade] oil.

“It’s an old wives tale” But changing the oil in an already noisy Gearbox, Transfer Unit or Diff won’t fix a thing.

Verifiable chain of supply

All bearings are from recognised bearing manufacturers such as Timken, SNR etc. Or direct from the main agent (OE). Therefore National Gearboxes are able to maintain verifiable genuine chain of supply and ultimately protect overall quality of product.